MenuMenu

- Compare. Save. Ship.

- Main Menu

- How It Works?

- Shipping Services

- eCommerce

- Learn

Warehouses have many moving parts, from the machinery doing the extra-heavy lifting to the people keeping things running. So, how do you keep tabs on all these different warehouse operations? With warehousing logistics.

Because of this essential part that logistics and warehousing play in business operations, the demand for this support system is expected to grow more than 5% in the coming years (particularly for the e-commerce industry).

Understanding how warehousing and logistics work means starting from the basics. Here we’ll dive into everything you need to know about warehousing logistics.

Before getting into the technical parts of logistics warehousing, it’s important to understand the definition of ‘warehouse logistics.’ Put simply, it’s planning, monitoring, and understanding every moving part of a warehouse, from inventory storage and movement to safety and security.

Warehousing logistics is a more holistic and long term look at warehouse operations. It focuses on a warehouse’s internal flow and processes. It includes organizing and maintaining cost effective operations, tracking inventory, and even customer satisfaction levels.

Warehouse management, on the other hand, focuses on the movement of inventory coming in and going out of the warehouse. In other words, it’s related to warehousing distribution needs like receiving and shipping inventory.

There are many different elements of warehousing in logistics terms. Here are some of the key terms for logistics and warehousing you need to know to make informed decisions:

This impacts the overall supply chain management process of taking a raw material and delivering a final product to customers. It relates to how and where products are stored and how products are moved through the warehouse system to get to where they need to be.

Inventory management includes:

These factors help warehouse operators figure out how best to arrange inventory storage and to create centrally located hubs for specific processes (like packing orders).

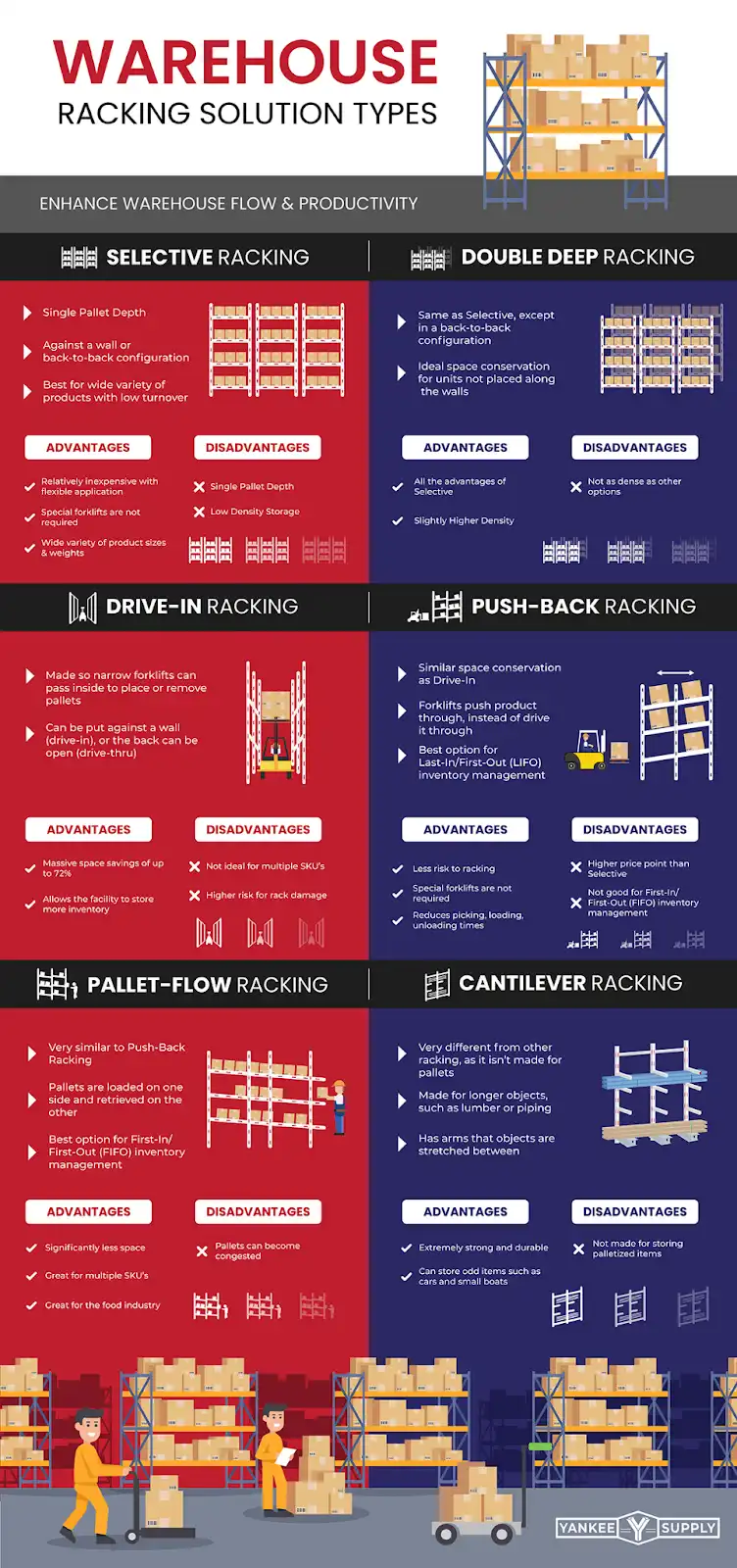

The process of storing products is more complex than simply placing an item on a shelf. With warehouse logistics, you can plan the best storage option (like the best type of shelving or storage rack) and storage location based on the product and typical picking and packing needs.

Looking at the flow of inventory within the warehouse also provides a framework for inventory management—just to make it easier to keep tabs on stock levels and reduce delivery times. It also ensures that customer services related to warehousing (like returns processing) have the space and resources needed.

While the use of automation for warehousing services has grown by 80% in the last five years, (and over 67% of warehouses are planning to implement mobile devices to streamline operations), there are still people there keeping things running. This is why when you think of warehousing logistics, you also need to consider the human factor.

Logistics and warehousing companies look out for people in all manner of functions. This includes people’s on-site presence, their ability to move through the space, and their ability to do this all safely.

Personnel management involves training for moving through the warehouse safely and for following standard operating procedures. They also determine staffing levels for day-to-day operations and busier seasons.

Safety and security are about protecting both people and inventory. Safety measures and protocols include the use of equipment to reduce repetitive and harmful motions for people working in the warehouse.

Regular maintenance of storage systems and warehousing equipment keeps things operating safely for people and protects inventory and equipment. (Security systems for warehouses may also include cameras, on-site security guards, and access controls.)

Each of these components plays a different role in how well a warehouse is working. And, of course, each is closely linked to the functioning of the other. Warehouse logistics is about implementing systems and procedures to help each component interact with each other as time and cost-efficiently as possible.

Source: Pexels

With so many moving parts and complicated processes to streamline, what are the payoffs of putting time and energy into perfecting a logistics system?

Mistakes made by people account for 46% of warehouse issues and concerns. When things are organized for an easier flow of work, it can help reduce the mistakes people make. This results in more accurate order fulfillment and happier customers.

Inventory management becomes easier with strategic storage. Inventory stock levels are more accurate, and with accurate information, customers can easily determine if you have what they’re looking to buy.

That thoughtfully created warehouse design, also helps people use the space more efficiently. How? By having the relationships between the inventory being stored and their proximity to packing stations taken into consideration.

Rather than spending time trying to find products, staff are easily able to find goods based on warehouse planning. Less time is spent searching for products, reducing costs associated with picking and packing.

Did you know…  Source: Yankee Supply |

When things are running smoothly it has an effect on the person at the end of the line: your customer. When orders are fulfilled and processed quickly, you’re setting yourself up to deliver a great customer experience. This keeps customers coming back.

All these benefits come together to bring your business increased revenue. When things run smoothly, you reduce costs associated with operations and human error. Each of these, directly and indirectly, impacts your bottom line.

To enjoy these benefits, there are some best practices to include in your warehouse logistics system. These include:

When it comes to your e-commerce business, outsourcing your warehousing is a simple way to keep your business operating smoothly. And, at Ship Expert, we can take on your Canada warehousing & logistics needs for you with our warehousing and fulfillment services.

We not only save you the headache of developing your warehousing systems, we also offer savings on shipping, easy integrations, and an easy-to-use platform for keeping tabs on all operations.

Featured Photo Source: Pexels

Director, Ship Expert

Greg Woo is a seasoned expert in the logistics and distribution industry, with a career spanning over two decades. He has a comprehensive understanding of shipping and distribution needs, and has extensive experience integrating with e-commerce stores as well as customer specific WMS (warehouse management systems) and ERP’s (enterprise resource planning software). His tenure in the industry and established courier and LTL partnerships have allowed clients to benefit from reduced shipping expenses, as well as improved operations through software and specialized integrations.

Greg is currently the Director at Ship Expert Inc., a role he has held since February 2015. Prior to his role at Ship Expert, Greg held significant positions at Juxto, a telecommunications and managed internet service provider.